1) Thickness: 0.017-0.03MM

1) Thickness: 0.017-0.03MM

2) Width: 300MM 450MM 500MM

3) Length: as your request

4) Color: transparent/clear,black,green,and so on

5) Net weight: on buyer's option

6) Packing: cartons or pallets.

Product features:

1.100% New material and accept sample order.

2.Excellence and beautiful, the high grade product.

3.Easy to be pulled out and cut.

4. Transparency and no drape and even thickness.

5. Easy to use, can be recycled.

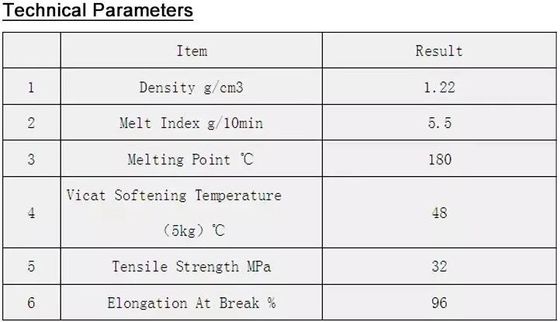

PVA water soluble film

Specifications

Plastic Film

100% new raw material, LDPE , UV resistance

Thickness: 12 mic --50mic --300 mic .

Colour: Transparent, Black, Red, Blue, Green, etc.

The main products of the company are polyvinyl alcohol (PVA) materials, films and bags etc. We have manufactured a series of products of water-soluble PVA bags for various uses.It could be processed according to customers demand of any size and specification.the water-soluble PVA bags are divided into the inner packing bags and the outer packing bags. Their characteristics are as follows:

1,It will dissolve competely under the normal water temperature(20±5℃) after 5-18 sec.

2,Its final products are CO2 and h3O, non-toxic and non-pollution;

3,The inner packing bags can dissolve completely above 3 ℃, while the outer packing bags can issolve completely above 80 ℃.

4,Printing can be done on both the inner packing bags and the outer packing bags, with clear handwriting, and oil ink and bags will dissolve together.

5 The water-soluble bag has no static electricity, h3 stretching intensity and even tensity .

6,The inner packing bags has heat sealing or tying with the water-soluble rope, while the outer packing bags can have nylon string and self-adhesive foil.

7,The size of water-soluble packing bags can range freely between 4cm*4cm---120cm*120cm.

8,Can be weighted exactly, no waste.

Food Grade POF shrinkable label Shrink Film

Product Name: Polyolefin POF Heat Shrink Wrap Film

Material: PP + PE

Shrinkage ratio: over 60%

Thickness: 12.5micron (50gauge), 15micron (60gauge), 19micron (75gauga), 25micron (100gauge)

Roll width: 200mm (8") to 1600mm (80")

Roll length: 800m to 1600m for center-folded, 1600m to 3200m for single wound

for standard sizes, please refer to the SPECIFICATIONS below

Type: single wound, corner folded (also called center-folded,), tube

Specifications :

| Thickness (mic/gauge) | 15/ 60 | 19/ 75 | 25/100 | 30/120 |

| Width (mm) | 100-2100 | 100-2100 | 100-2100 | 100-2100 |

| Length (Single Wound) | 2700m | 2100m | 1600m | 1800m |

| Length (Center Fold) | 1335m | 1067m | 800m | 900m |

| Length (Tubular) | 1335m | 1067m | 800m | 900m |

Packaging Details :

Bags or film rolling on the 3" paper core ,With film bag covered on outside .

each sides of core with plastic cap

All rolls loading on plastic pallet (1300*1100*150mm)

For container loading ,suggest use gusseted fold type

20ft: 8pallets/8-10tons

40ft: 16pallets/16-23tons

Delivery Time:

FCL container or LCL container,by sea or by air

20 days after receiving the deposit payment

12mic 19mic heat shrink Perforation POF Shrink film

1. Shrink film thickness and width:

Thickness:10mic, 12.5mic, 15mic, 19mic, 25mic and 30mic etc.

Width:100-2200mm

2. Shrink film grade:

Can be divided into normal grade, medical grade, high strength grade;

Can be made of tubular film, L-type fold film and single film,

Can be processed into tube bags, flat pockets, ladder bags, round bags and so on.

POF Shrink film FEATURES

Cast film, high clarity and shrink rates at transverse direction, well distributed thickness, anti-static treatment for increasing printing and labeling speed.

-Suitable for a broad range of applications: tamper evident seals, Pre-forms, and full body sleeve labels.

-Low shrink initiation temperature.

-Long shell life at recommended storage temperatures.

-Excellent for printing high quality graphics.

-Ideal for high speed applications.

-Can be printed without surface treatment.

-Lighter and more cost effcient than tranditional packaging.

| Thickness | 12mic/50g | 15mic/60g | 19mic/75g | 25mic/100g |

| Wideness | 100mm-2200mm | 100mm-2200mm | 100mm-2200mm | 100mm-2200mm |

| sinlg would length | 3100m | 2667m | 2133m | 1600m |

| center folded length | 1550m | 1332m | 1067m | 800m |

POF film type

POF film: Center-fold/Single wound/POF shrink bags,Printing on film,Cross-linked film,Anti-fog film,Micro-perforated film,Pre-perforated film etc

POF package shrink film application:

The POF shrink films are used for labeling and packing products in various industries:

-Food & beverage industries: Mineral Water, Soft Drinks, Liquors, Pickles, Jams, Jellies, Fruit Juices, Tea, Coffee,Spices, Ghee, Edible Oils etc. in Bottles / Cans / Jars

-Printing & Packaging industries

-Cosmetic & Toiletry industries: Powder, Perfume, Hair Oil, Shampoo etc. in bottles & jars

-Pharmaceutical industries: Liquid Bottles, Tablet/Powder, Containers & Jars

-Electrical industries: for bus bar application and insulation tape packing

-Stationery & Writing instrument industries

POF film Packing details:

one roll of pof heat shrink film in one carton box; tens of cartons in a pallet;

10~12 pallets pack into 1*20 ft. container;

20~22 pallets load into 1*40 ft. container

Characteristics:PE shrink film is made from high-pressure polythene mixed with relevant auxiliary materials through huffing once, so it features tenacity, softness, impact-resistance and unbreakable.

Characteristics:PE shrink film is made from high-pressure polythene mixed with relevant auxiliary materials through huffing once, so it features tenacity, softness, impact-resistance and unbreakable.

Varieties: We can make tube-film, L-shaped opposite folding film and single layer film according to customers' request, as well as pipe-bags, flat-orifice bags, trapezoid bags.

Main purpose: suitable for packing of beverage, mineral water, beer, stacks, building materials, metalwork, dairy, glass bottles, and other large equipment and goods.

| Width | 250mm-750mm |

Tearing strength | In transverse direction

≥40KN/m |

| Thickness | 40um-250um | In machine direction

≥40KN/m |

Shrinkage rate | In transverse direction

15%-20% |

Tensile strength | In transverse direction

≥12Mpa |

In machine direction

60%-70% | In machine direction

≥12Mpa |

| Shrinkage temperature | 150ºC-220ºC | Breaking elongation | ≥200% |

| Specific weight | 0.93g/cm3 | Interior diameter of roll core | 76mm |

1) Waterproof, Oil-proof, Moisture-proof, Anti-corrosion; Tear-resistance,

Dust resistance.

2) one-six colors printing can be added as per client specs.

3) Product types: single layer, tubing, bags, centerfold rolls.

Product Name: Polyolefin POF Heat Shrink Wrap Film

Material: PP + PE

Shrinkage ratio: over 60%

Thickness: 12.5micron (50gauge), 15micron (60gauge), 19micron (75gauga), 25micron (100gauge)

Roll width: 200mm (8") to 1600mm (80")

Roll length: 800m to 1600m for center-folded, 1600m to 3200m for single wound

for standard sizes, please refer to the SPECIFICATIONS below

Type: single wound, corner folded (also called center-folded,), tube

| Thickness | Micron | | 12.5micron | 15micron | 19micron | 25micron |

| Gauge | | 50gauge | 60gauge | 75gauge | 100gauge |

| Density | g/cm³ | | 0.922 | 0.922 | 0.922 | 0.922 |

| Tensile Property (MD/TD) |

| Elastic Mouduls | N/mm² | ASTM-D882A | 330/450 | 340/450 | 350/450 | 360/450 |

| Tensile Strength | MPa | ASTM-882 | 110/110 | 110/110 | 110/110 | 105/105 |

| Elongation at Break | % | ASTM-882 | 105/110 | 105/110 | 110/110 | 110/115 |

| Seal Strength | g/cm³ | Internal Method | 610 | 870 | 1025 | 1250 |

| N/mm² | 40 | 57 | 53 | 49 |

| Tear Propagation | g/cm³ | ASTM-D1938 | 6 | 5.5 | 9.5 | 14.5 |

| COF film to film | Adim | ASTM-D1894 | 0.2 | 0.2 | 0.2 | 0.2 |

| Free Shrink at 130ºC | % | ASTM-D2732 | 70/70 | 70/70 | 70/70 | 70/70 |

| Optical Property |

| Haze | % | ASTM-D1003 | 1.1 | 1.3 | 1.8 | 2.3 |

| Gloss | % | ASTM-D2457 | 135 | 135 | 135 | 130 |

1. High transparency, fine luster

2. High shrinkage, up to75%

3. High heat sealing and intensity, suitable for manual, half antomatic and

high-speed antomatic packaging

4. High cold resistance, keep flexible below-50 degree celsius, adapt to

storage and transport in cold weather.

5. Environment-friendly, nontoxic and meets US. FDA standard

6. Prevent damp and dust

7. Low package cost, better than paper box and other materials

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!